Description:

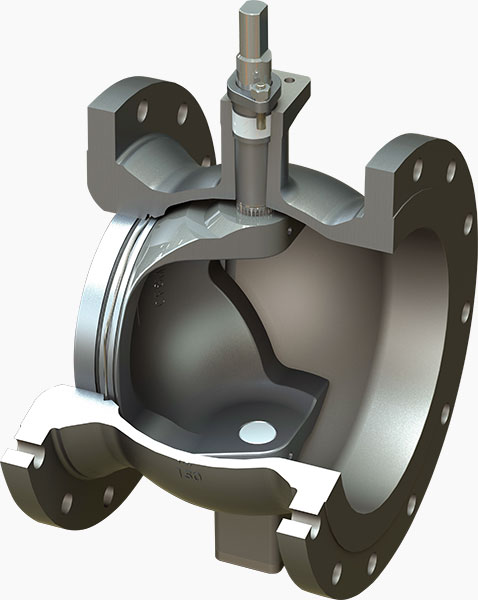

Flow-Tek Series 19 is a versatile Segmented Ball Valve designed for throttling or on-off applications in various industries including pulp & paper, chemical, power, oil & gas, and mining.

The valve features a characterized ball segment for high rangeability with splined stem connection for precise control, maintenance friendly segment-stem assembly, low friction shaft and thrust bearings for longer life, integral actuator mounting pads, and interchangeable seats.

Valve Body

- One piece body design which offers greater rigidity against fluctuating pipe loads.

- Eliminates the leak path associated with two piece body designs.

- Available in Flangeless and Flanged Ends.

Ball Segment

- Carefully designed with characterized V-port to offer rangeability in excess of 300:1, ideal for throttling applications in high consistency pulp services or slurry applications.

- Perfectly ground spherical surface with rounded edges ensure lower operating torques for metal seated valves.

- Hard coated spherical surface prevents galling.

- The segment is carefully designed for optimum flow.

- The seat is supported during higher openings to prevent rocking motion and possible failure of the valve.

Descripción

Specs:

- Flow Characteristic: Equal Percentage

- Size Range: 1″ up to 12″ (DN 25 – DN 300)

- Face to Face Dimensions:

- Flangeless:

-

- Class 150/300: Flow-Tek Internal Standard

- Class 600: ANSI/ISA 75.08.02

-

- Flanged:

-

- Class 150/300: ANSI/ISA 75.08.02 (ISA S75.04) /IEC 60534-3-2

- Class 600: ANSI/ISA 75.08.02

-

- Flangeless:

- Flanges: ASME B16.5

- Seat Tightness:

- Metal Seat: Class IV per IEC 60534-4 /ANSI/ FCI 70-2

- Soft Seat: Class VI per IEC 60534-4 / ANSI / FCI 70-2

- Temperature Range:-40°C to +260°C ( -40°F to +500°F)

- Pressure Ratings:Class 150/300/600

More technical information https://www.bray.com/ball-valves/control-valves/segmented-ball-valve